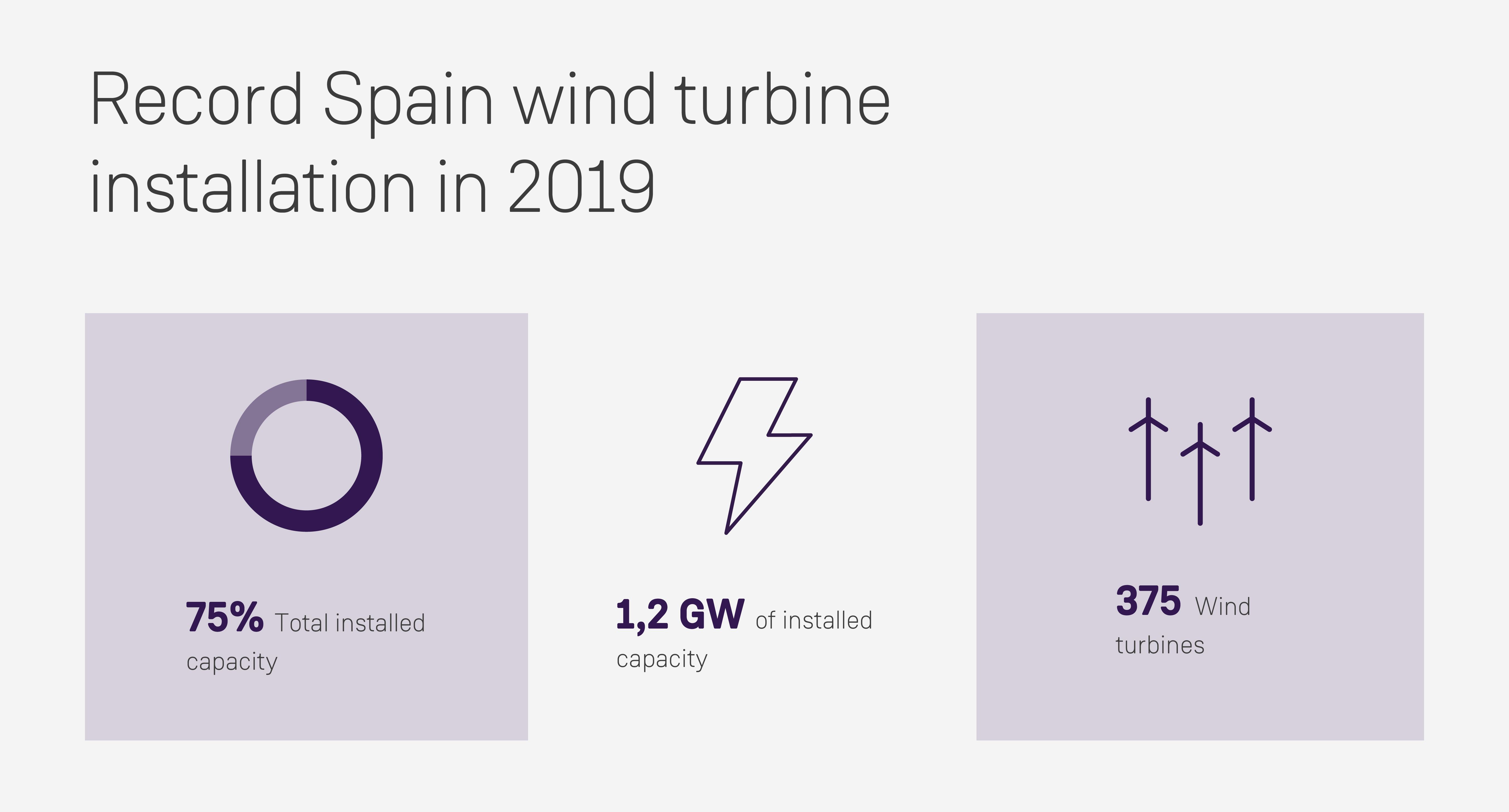

The Spanish business closed a successful year in 2019 with the installation of a new record of 1.2 GW, or 375 wind turbines, the highest amount of any year in the last decade. This was equal to 75% of the total installed wind energy capacity in the country. The milestone represented a five-fold increase in the installation figure from the previous year (217 MW), and was up from just 29 MW installed in Spain in 2017.

Showing Siemens Gamesa’s commitment

to the Spanish market, most of the turbines were designed and

manufactured in plants within the country, which helped to create local

employment and boost the supply chain. In total, turbines were supplied

to 15 customers in 30 wind farms located in the Spanish regions of

Aragon, Andalucia, Galicia, Castille and León, and Navarre.

“We start the year with some very good news! Achieving this record in

Spain was made possible thanks to the daily work and commitment of our

staff. Their engagement is fundamental to achieving such important

milestones as this,” affirmed Enrique Pedrosa, Onshore Chief Regions

Officer.

Of all of the turbines supplied, over 80% were the SG 3.4-132 model, one

of the company’s most efficient, with a rotor diameter of 132 meters

and nominal power of more than 3 MW. Siemens Gamesa is supplying

machines with increasingly larger rotors as it transitions to its 4.X

platform.

The aim is to contribute to a future powered by clean, affordable,

reliable, and infinite electricity. These wind turbines combined make it

possible to cover the energy needs of nearly one million homes. In

addition, they prevent the emission of 3 million tons of CO2 into the

atmosphere, and offset the same amount of emissions as 50 million

trees.

- 0105

“I think we are not yet aware of the

incredible record we have achieved in Spain: the installation of 1.2 GW

in one year, with a high degree of customer satisfaction, is something

very few companies can do,” said Roberto Sabalza, CEO Onshore SE&A.

“Three out of four turbines installed in Spain in 2019 were Siemens

Gamesa turbines, which shows how we are consolidating our leadership in

Spain,” he affirmed.

According to Roberto, this achievement is important for a number of

reasons. “First, it shows we have some incredible teams that have

demonstrated their ability to work hard and efficiently – this

combination is the key to success. Second, this record installation had a

very positive impact on operations and job creation in Spain, as

suppliers are mainly local. And third – and this is very important as

well – with this 1.2 GW of new wind power, we must be very proud of our

contribution to the energy transition in Spain, the reduction of CO2

emissions in our country, and finally to the sustainability of our

world.”

The logistic challenge

Installing 1.2 GW in just one year was a special challenge for the Construction department.

“Managing such a large amount of

resources in such a short period of time has not been an easy task at

all, but we have delivered on time thanks to the amazing team effort and

dedication,” says Construction Manager Stephane Jacob.

The numbers are impressive: a total of 15 different main cranes from

seven different companies – six from Spain and one foreign company – and

17 different assembly teams. “Coordinating all these different

suppliers to make sure we were meeting our deadlines was an incredible

puzzle,” added Stephane. In total, the Construction teams have dedicated

more than 850,000 hours to the installation of the 1.2 GW.

Ballestas and Casetona

It’s difficult to select specific

projects to highlight among all of the intense activity carried out in

2019, but if we have to focus on one of them in particular, it would be

the Ballestas and Casetona wind farm. Located in the province of Burgos,

it has an installed capacity of 69.3 MW, with a total of 20 model

SG3.4-132 (114m) wind turbines.

Eneko Díez, Program Director Onshore SE&A, outlined the complexity

of the project. “It is a Siemens Gamesa WFS (Wind Farm Solutions)

project, which means that Siemens Gamesa has been in charge from the

outset of every aspect through the whole processes, from the

installation of the wind mast to the validation of the wind resources

and the location, as well as the development phase, including closing

the agreements with the landowners, authorities, and the utility. Also,

the construction of the whole infrastructure – the Engineering

Procurement, and Construction contract – and the connection to the grid,

the commissioning phase, and finally the sale of the wind farm to a

relevant utility were all in scope,” said Eneko.

For Eneko, one of the biggest challenges was the grid connection. “We

needed to adapt in a very short period of time the existing high voltage

line connection to be able to absorb the new power capacity. The whole

team involved in Ballestas and Casetona, the largest Wind Farm Solutions

project in 2019, should be very proud of the great work done on a very

complex project with tight deadlines,” he explained.