When Swedish Bruzaholm wind farm is completed next autumn it will not only produce fossil free power. It will also be a shining example of how sustainable procurement can spur innovative ideas and bring the carbon footprint from construction down to a minimum.

Facts Vattenfall Sustainable Procurement

We aim to be net zero by 2040 and have set a supply chain target on reducing the greenhouse gas emissions from purchased goods and services of 50% until 2030.

- Vattenfall joined First Mover Coalition as a founding member in 2021 to driving the transition towards a fossil free future

- By 2030, our minimum commitments under the coalition include to purchase:

- 10% breakthrough steel

- 10% near-zero concrete

- Business Area Wind committed to the international initiative Steel Zero initiative of Climate Group:

- Using 50% low emission steel by 2030

- Setting a clear pathway to being net zero by 2040

Read more about our work on sustainable procurement in the Vattenfall Annual Report 2023 here

In Bruzaholm in the south of Sweden, Vattenfall is erecting a 21 turbine onshore windfarm. From autumn 2025 it will deliver an annual output of 460 Gwh of fossil free power, an important contribution to the electricity supply in southern Sweden.

What truly sets this project apart is the meticulous effort dedicated to minimizing the carbon footprint at every step of the construction process.

Arthur Besse, Head of Onshore Wind Procurement explains:

“At Vattenfall we are committed to become climate neutral across our value chain until 2040 and we have the ambition to half our greenhouse gas emissions from purchased goods and services by 2030. The Bruzaholm project is?a concrete example of actions we are making to reduce the climate impact when we build our windfarms.”

This project helps Vattenfall actively work towards minimizing the carbon footprints in the supply chain which is an important element on Vattenfall’s road to decarbonisation.

The most tangible example of this commitment lies in the concrete. In Bruzaholm, the carbon emissions from the concrete are the lowest possible, even lower than what is typically classified as eco-concrete.

“The concrete we use in Bruzaholm has a CO2 footprint of 211 kg CO2 equivalents per cubic metre, this is 12 per cent lower than our own internal target for Eco-Concrete. The extra price premium is less than 2 per cent. As we will need some 7500 cubic meters for the 21 foundations, it will make a significant difference to the CO2 impact of the project but minimal impact to the budget,” Besse says.

According to the supplier the concrete achieves a 40% lower CO2 footprint compared to the industry benchmark for conventional concrete. The comparison is based on carbon emissions data, using a reference value provided by the Swedish Concrete Association, Svensk Betong.

Low carbon concrete is key to the wind supply chain to reach its net zero targets. Here it is used for the foundations in the Swedish Bruzaholm project.

Sustainability integrated in the procurement processes?

Low carbon concrete is key to the wind supply chain to reach its net zero targets. But for Vattenfall, this was only one of the measurements when planning for the Bruzaholm wind farm. Equally important was how the contractor for the ground works was selected.

Suppliers often face a difficult choice: submit the cheapest possible tender or include sustainable measures that inevitably increase costs. ?

For this project, Vattenfall asked suppliers to submit CO2 emission reduction ideas with independent pricing, which could be implemented as part of the project. This allowed suppliers to present the lowest possible base price while separately offering a list of options to lower emissions. Sustainable measures were a key criterion in the scoring and selection process. The contract was awarded to Kanonaden Entreprenad, and a number of their proposals were included in the final contract.

“Kanonaden Entreprenad, was the perfect match for us. To use this extra CO2 lean concrete was actually their suggestion, and they also brought a good deal of other ideas, from using bio diesel for all site machinery, to the use of recycled plastic pipe for conduits and site signage, and planning the groundworks? to avoid unnecessary transportation of rock masses to and from site. This model for procuring goods and services has proved to be really efficient and successful for all parties, and will now be used as a blueprint for coming projects,” Arthur Besse says.

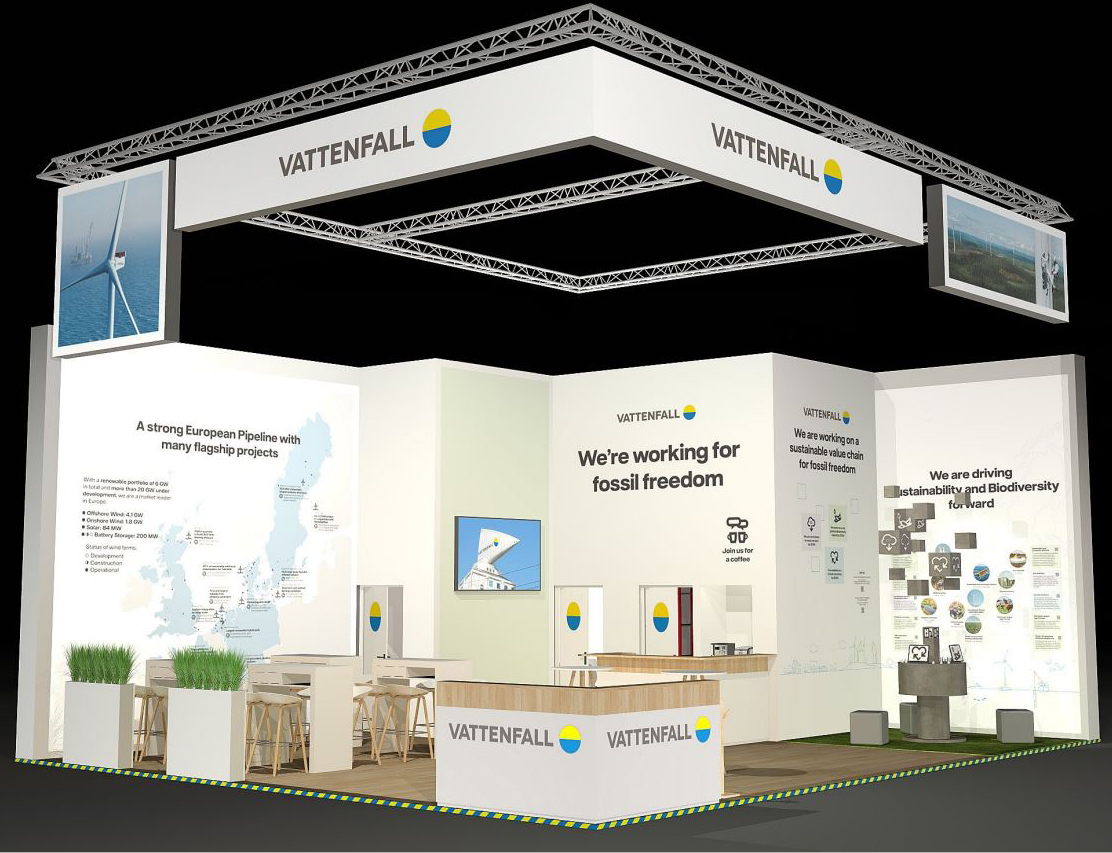

Vattenfall at the WindEnergy trade fair in Hamburg, September 24 to 27, 2024

Join the global on & offshore event – WindEnergy Hamburg: Hall B6 booth 339

We invite all visitors to meet us at our booth, and to connect with our team of experts. This is a fantastic opportunity to learn more about our innovative initiatives to enhance Biodiversity and Sustainability in our developed constructed or operated wind farms.

The usage of low-CO2-concrete for Onshore Wind farm foundations will be at centerstage.

Connect with our staff to discuss how to collaborate with Vattenfall to shape the future of our wind energy projects in the field of development, construction, operation or with power purchase agreements (PPA’s) to decarbonize the industries in partnership.